9T Labs and ANSYS partner in composite design and simulation tools

As the deployment of 3D printers and tape laying machines increases, part complexity of composites rises simultaneously. Manufacturers aim to reduce production time, part weight, material waste and ultimately costs by challenging conventional geometries and fiber lay-ups. 9T Labs, the Swiss system provider for digital composite production, and ANSYS, the leading engineering simulation company, now provide an integrated design and simulation workflow to give engineers the means to intuitively establish such improved designs.

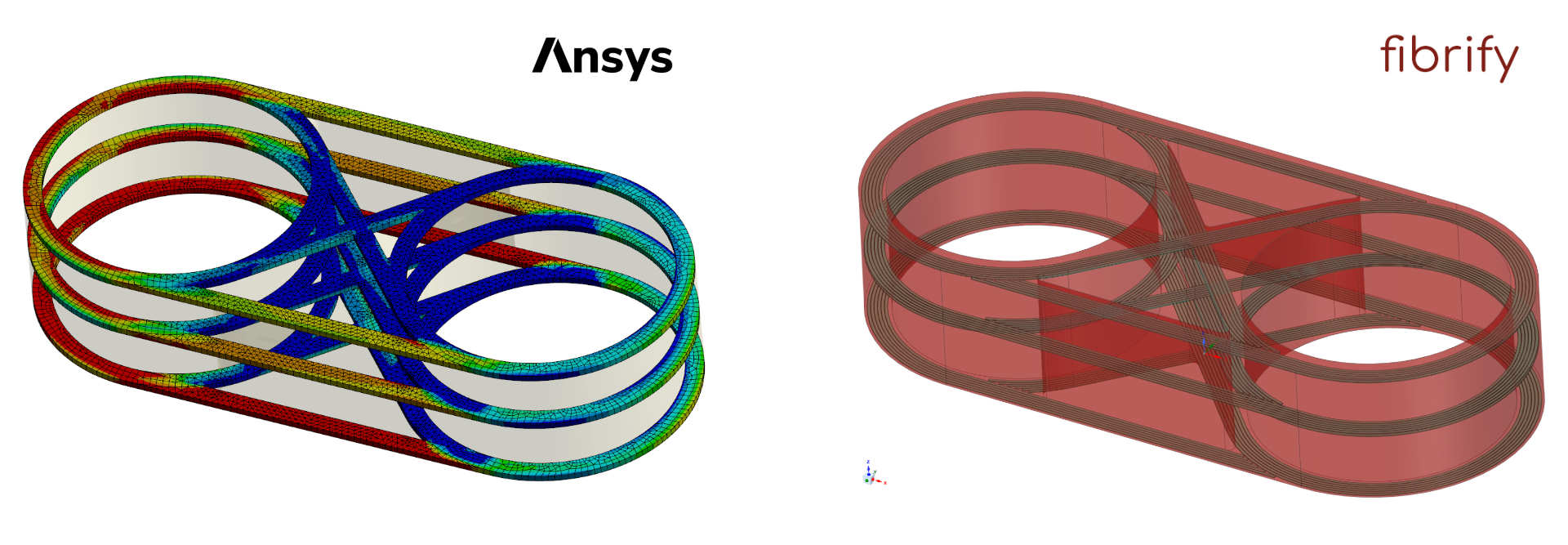

The new releases establish a convenient synergy between 9T Labs’ fibrify software and ANSYS’ Composite PrepPost (ACP) that helps you to create the best lightweight parts without producing or testing them in advance. A new interface in ACP can directly import complex fiber lay-ups established in fibrify and converts them automatically into a finite element model. Parts composed partially of neat plastic in addition to a fiber lay-up, as often the case in composite 3D printing, can also finally be simulated easily. During an iterative process of geometry design and fiber lay-up composition in fibrify and running simulations through ACP, an optimal design can be found.

Subsequently, fibrify allows users to connect to 9T Labs’ equipment, start production and monitor the process. In the Build Module, a preform is made after which the Fusion Module consolidates the part for end use in a structural application. 9T Labs and ANSYS will present the solution at JEC World in Paris from May 12-14. 9T Labs offers fibrify as part of its Red Series products, on order from March onwards.

Join the 9T Labs webinar on Thursday 5 March: https://app.livestorm.co/9t-labs/launch-red-series

Zurich, Switzerland. February 28, 2020. // 9T Labs